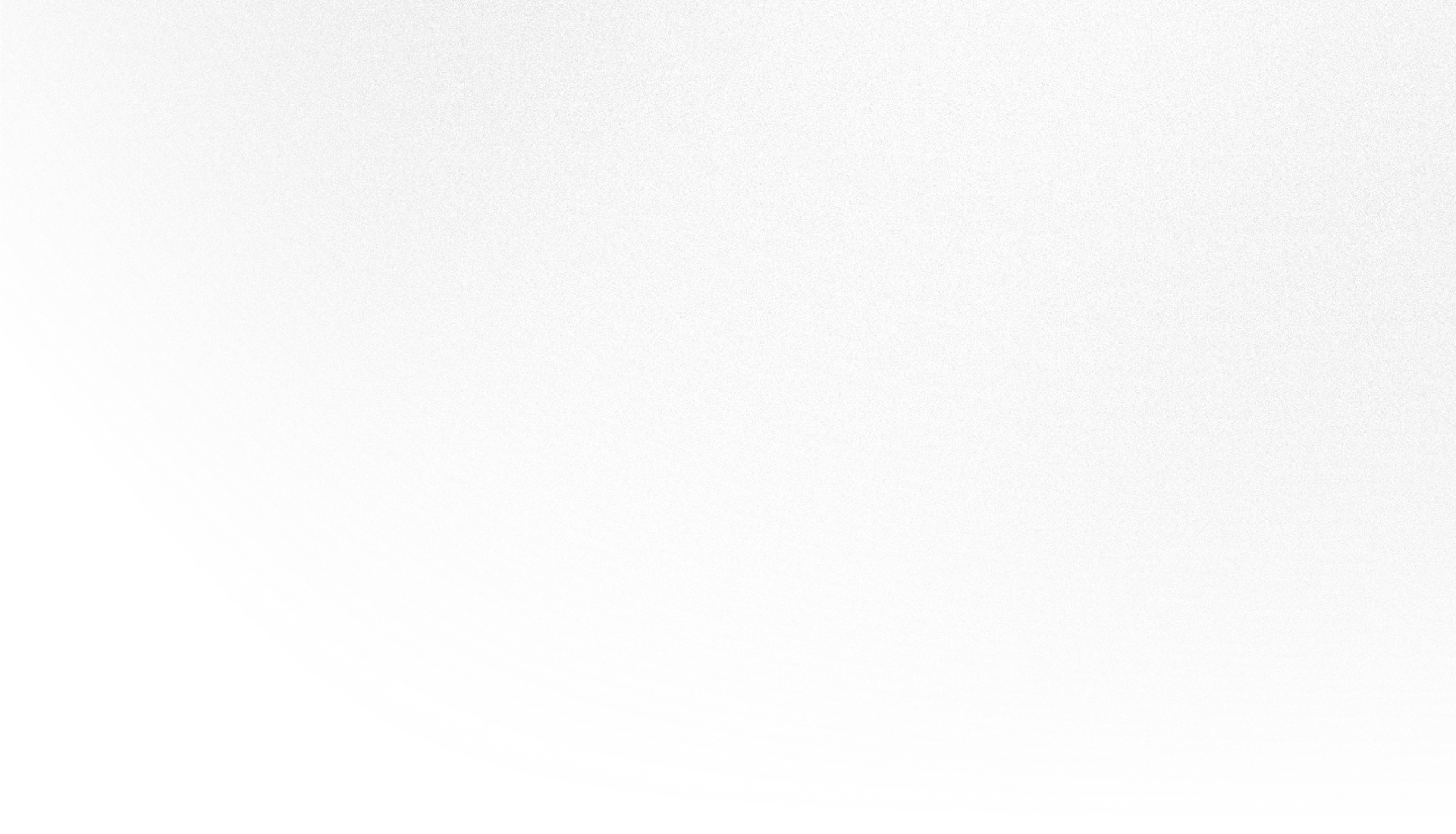

Machinery and Equipment Manufacturing

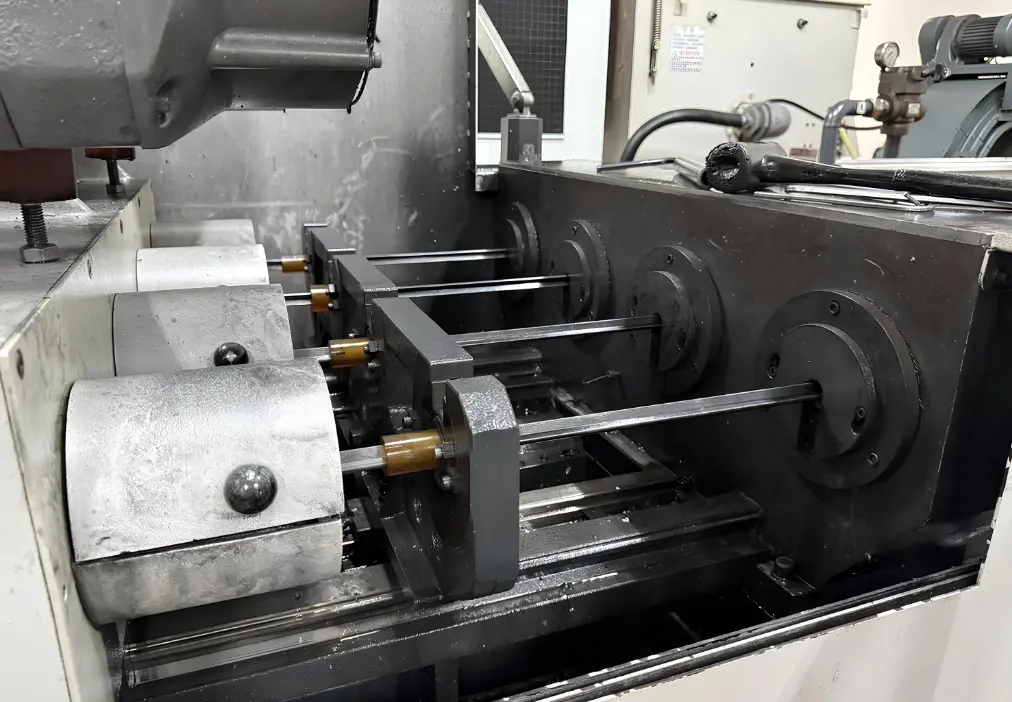

We are equipped with high-precision machinery and advanced automation technologies, specializing in precision machining and mechanical design, giving us a distinct competitive advantage.

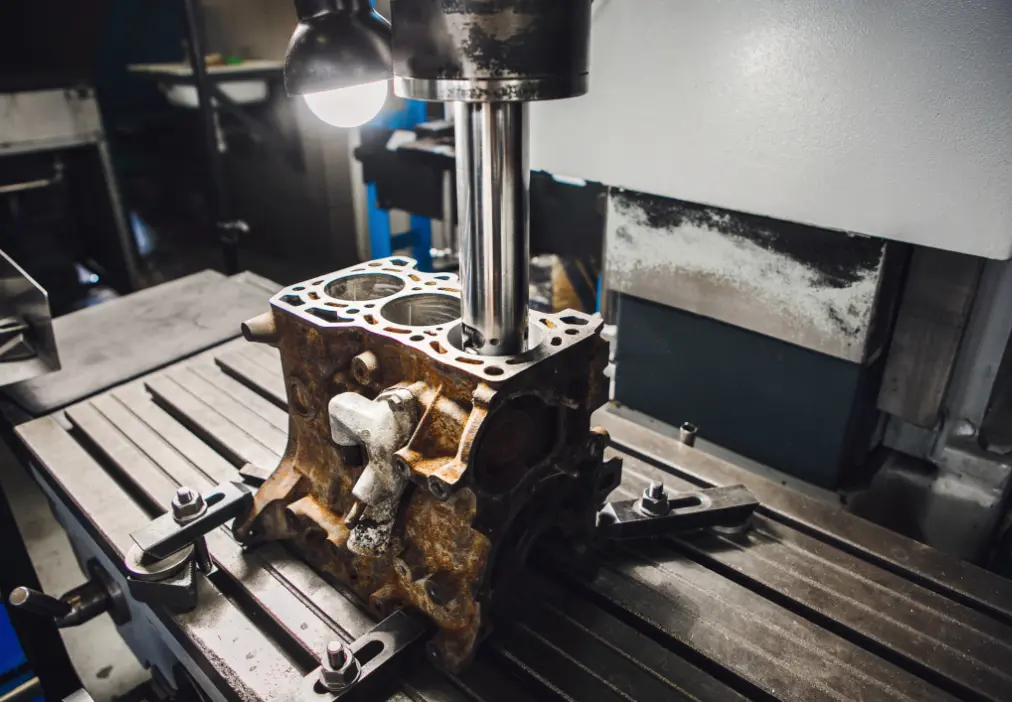

Advanced Software Support for 5-Axis Machining

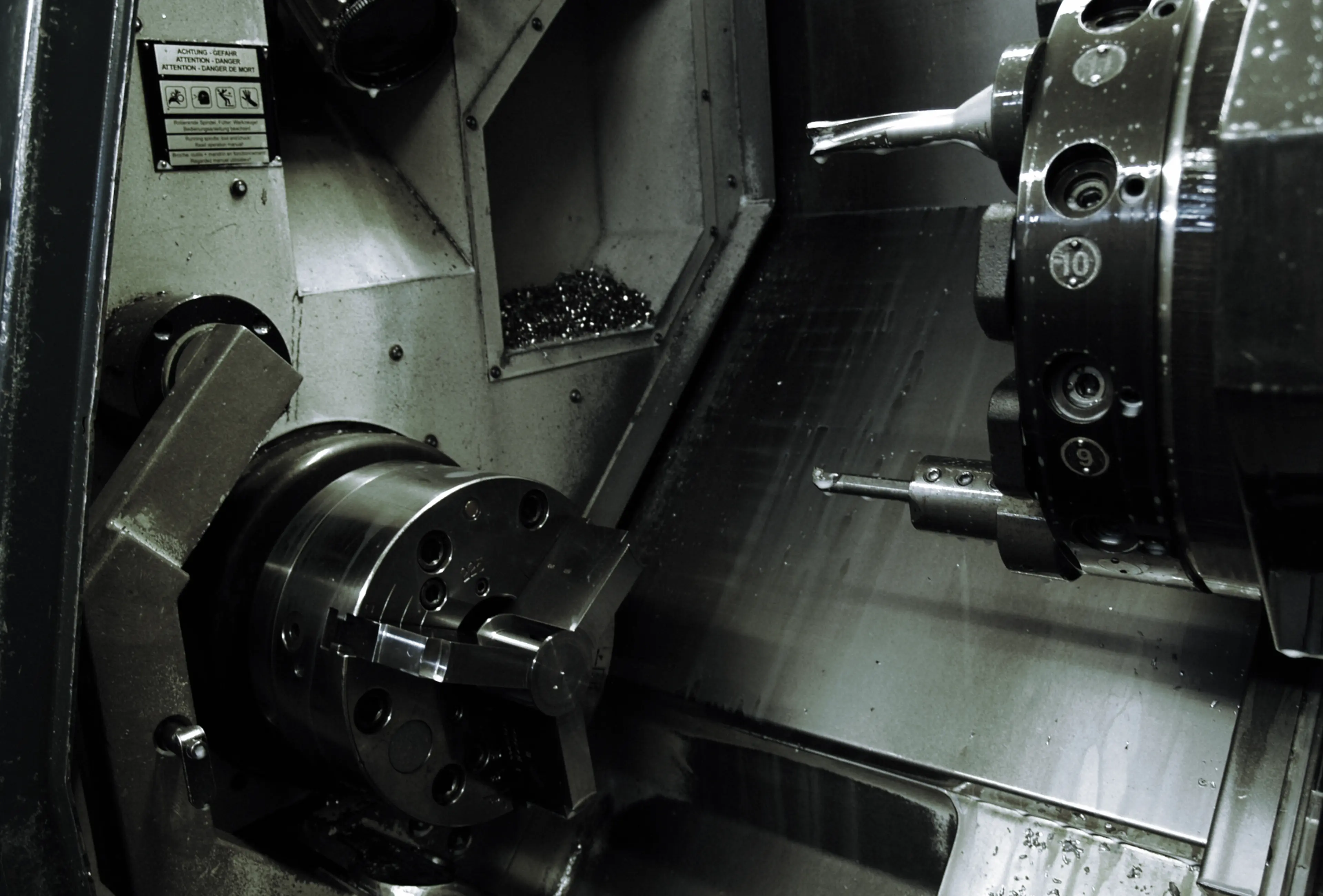

We design and manufacture a wide range of customized parts based on customer requirements, quickly responding to the needs of various industries and enhancing market competitiveness.

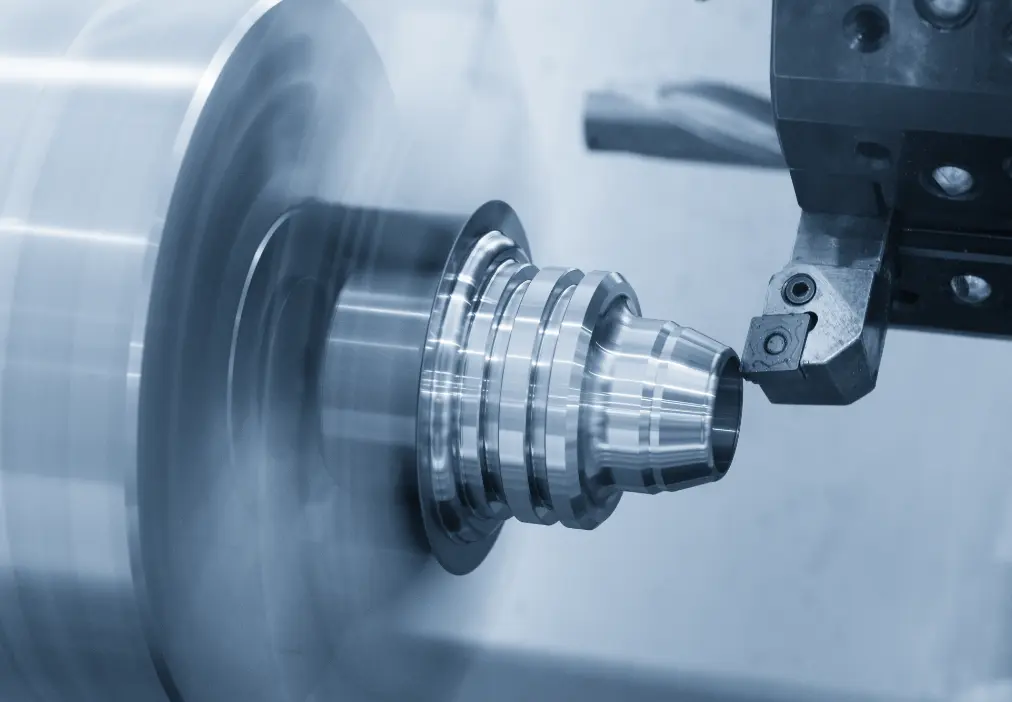

Real-Time Competitiveness Management

Through our machine-to-network (IoT) system, we can monitor real-time production status on the shop floor. This allows us to quickly respond to unexpected customer demands and maximize production efficiency.

Diverse Manufacturing Capabilities Across Industries

We offer flexible and diversified manufacturing services, with products covering a wide range of applications including automotive and motorcycle parts, agricultural machinery, high-end bicycles, lighting equipment, toy guns, hand tools, industrial components, machine tool parts, electronics, and medical device components.

Strong Commitment to ESG Practices

We place great importance on ESG implementation. Whether it’s carbon reduction, social responsibility, or corporate governance, we actively invest time and resources to drive continuous improvement.

We have completed our carbon footprint inventory report and have already achieved measurable results in low-carbon manufacturing processes.

In addition, we actively support employee training programs and participate in community engagement and public welfare initiatives.