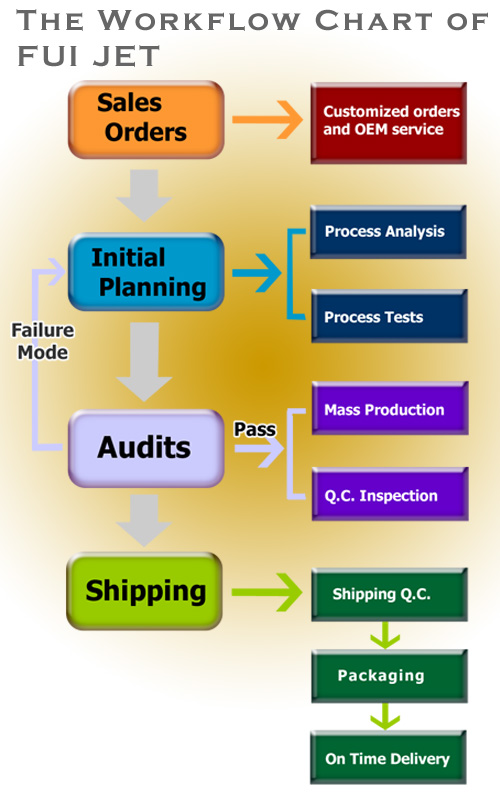

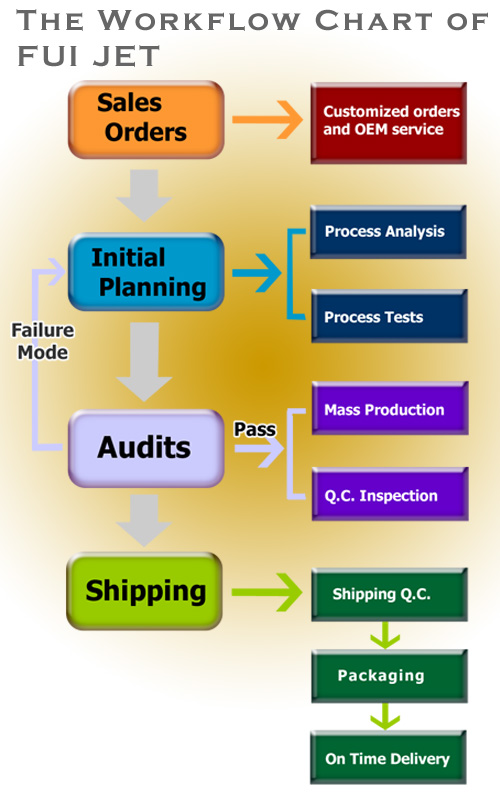

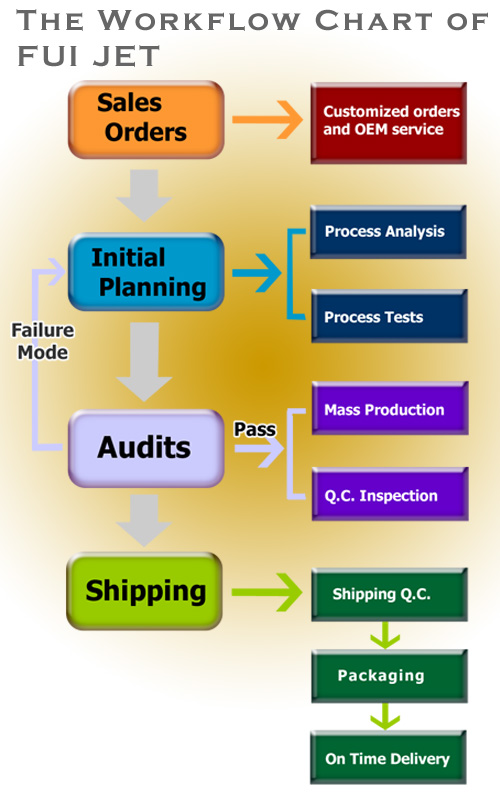

The first step in work is to fully understand customer requirements. Thus, when our sales take orders we always adhere to a customer quality satisfaction-oriented concept, and aim to become a service industry within the manufacturing industry.

After we receive an order, Fui Jet Tech will convene a work discussion meeting to focus on customers’ quality standard and technical requirements. Small teams are formed from sales, development, processing, quality control, and management department personnel to adequately discuss and exchange opinions, and to allow work colleagues to completely understand customer requirements and expectations.

To do good work, one must have the right tools. Pre-planning before mass production on the line is the most important key to achieving customer satisfaction.

This is Fui Jet Tech’s CAD/CAM drawing room. Professional R&D personnel use computer analysis, simulation, design, and drawing based on customers’ product characteristic, and set work planning and production procedures to carefully plan the production process.

This is Fui Jet Tech’s CAD/CAM drawing room. Professional R&D personnel use computer analysis, simulation, design, and drawing based on customers’ product characteristic, and set work planning and production procedures to carefully plan the production process.

The processing material must also be analyzed beforehand to ensure the reliability of the material.Fui Jet believes that high efficiency production capability comes from outstanding management. Processing simulation, including process planning, work piece program, and process tests must be conducted before work to strictly control production cost and delivery schedule. Fui Jet Tech applies standardization, do, check, action (SDCA) management to make sure that all work is precise.

If abnormalities are discovered after measurement analysis and statistics control then failure mode and effect analysis (FMEA) is conducted and the process is returned to the previous step to re-conduct pre-planning.

Products that match specifications are sent to process SOP review. This is where standard specifications for various materials, process procedures, and quality policy are established.

Check and self-management is conducted for the initial SIP piece to confirm the accuracy of the process.If the piece is within specification standard, then it can officially go on the line and enter mass production.

Products must pass strict quality control before they can enter the packaging line. Before packaging, a final shipping product inspection must be conducted.Product precision and stability, reliable delivery time, Fui Jet’s service orientation has resulted in high customer satisfaction. We are working hard to become the most valuable partner in your industry chain.