History & Milestone

|

1983 |

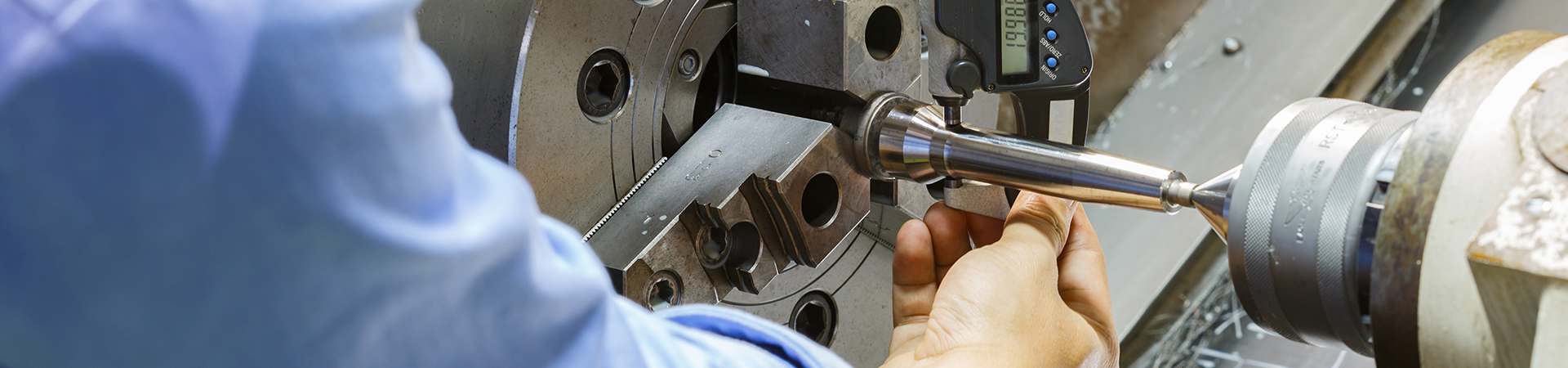

Started from 3 high-speed lathes, producing machinery parts. |

|

1987 |

Started production of electric tool parts |

|

1988 |

CHIEAN CHIANG IND., CO., LTD. was founded, engaging in auto parts production . |

|

1992 |

FUI JET TECH CO., LTD. was established. |

|

1993 |

With years of experience in manufacturing, began the production and machining for tooling and auto parts. |

|

2000 |

Purchased new factory and new equipments. |

|

2001 |

Entered into the areas of photoelectric tooling. |

|

2002 |

Authorized consultant company to improve our company’s management and planning of ISO Quality System |

|

2003 |

Purchased two-dimensional electronic projectors |

|

2004 |

Purchased sphericity gauges (accuracy 0.0002mm), hardness testers, surface roughness measuring gauge, concentricity gauge and other precision measurement instruments etc., increased product quality and competitiveness. |

|

2005 |

Passed ISO 9001 Certification. |

|

2006 |

Invested ten million in purchasing precision equipments and moved into areas of precision technology. |

|

2007 |

Purchased additional CNC precision grinding equipments and laser precision OD measuring instruments. |

|

2008 |

Purchased four-axis computerized drilling/milling/boring special-purpose machine |

|

2009 |

Purchased CNC internal-diameter grinding machine, CNC inner-hole grinding machine, and optics image measuring instrument and sphericity gauges |

|

2010 |

Purchased coordinate Measuring Machines, CNC lathe and vertical Machining Center |

|

2011 |

CNC lathe robotic arm purchased. |

|

2012 |

CNC vertical machining robotic arm and 4.5 spindle equipment. |

|

2013 |

Due to the requirement for business, the plant is moved to Fengyuan. |

|

2014 |

Profile meter and 2 units of ZEISS 3D Coordinate Measuring Machine purchased. |

| 2017 |

KEYENCE auto-optical projector purchased. |

| 2018 | Integration and re-plan production line and move to new factory. Import plant management system & Digiwin ERP system. |

| 2019 |

Brother SPEEDIO S500 & CNC vertical machining robotic arm and 4.5 spindle equipment & FANUC six-axis joint robot purchased. |